Sheet and tube laser cutting machine

Tube and plate laser cutting machine

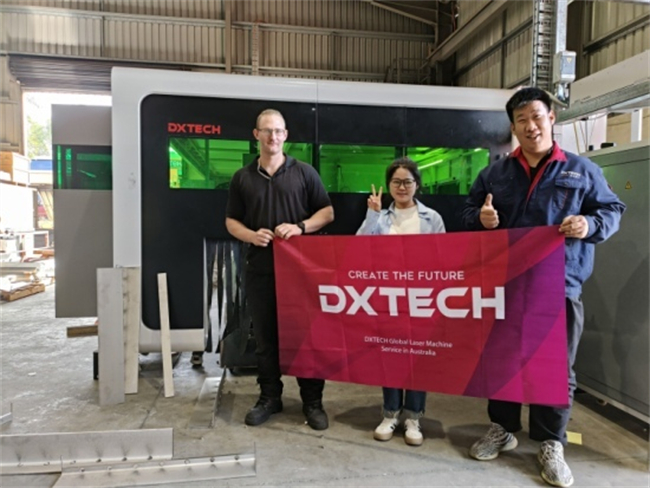

DXTECH specializes in fiber laser cutting machines for metal processing. Our machines offer high – quality, high – speed, high – precision, and high – efficiency performance, covering all metal processing needs.

We provide fiber laser cutters with powers from 1.5kW to 20kW, handling both conventional metals like carbon steel and stainless steel, and special materials such as titanium alloy.

Our diverse models and professional R&D team can customize solutions for your specific requirements, ensuring maximum cost – effectiveness. Choose DXTECH as your professional and efficient metal processing partner.

Customized Solutions

Fiber laser cutting machines in the 1.5kW to 20kW power range for high-speed cutting of thin plates to high-precision processing of thick plates.

Ultimate Performance Guarantee

ISO 9001 and CE certificates, the life of the whole machine is more than 100,000 hours, and the failure rate is lower than the average value of the industry by 40%.

Hassle-free global delivery

Provide free material cutting test, customized equipment selection plan by a team of engineers with 16 years of experience online 24 hours.

Best-Selling Tube and Plate Laser Cutting Machine

1530FL6T Open Type Sheet Tube Laser Cutting Machine

- Tube lengths of 3m or 6m are available.

- Dual cutting function: cuts plate and pipe

- Heavy-duty cast iron bed, aviation aluminum beams, more stable and sturdy, life expectancy increased by 30%

2560FPT Laser Cutting Machine for Metal Sheet and Tube

- 2500*6000mm larger machining surface

- 11-point lubrication system ensuring the machine‘s stability

- The material collecting trolley uses German corrugated tech. It has 2x better load – bearing & deformation resistance, doubling service life.

EPT1530 Exchange Platform Tube and Plate Laser Cutting Machine

- Switching platform for fast loading and unloading, increasing work efficiency by 60%.

- Support 1000W~6000W Laser Power

- Dual-purpose design saves more than 50% space

SPT Protective Exchange Table Metal Sheet Tube Laser Cutting Machine

- CE certified protective housing for safer and more environmentally friendly work

- Built – in control panel and independent electrical cabinet: 50% lower electrical failure risk.

- Top negative pressure fan and bottom zoned dust removal: 2x dust removal efficiency improvement

More Tube and Plate Laser Cutting Machine

High Perfomance Fiber Laser Tube Cutting Machine

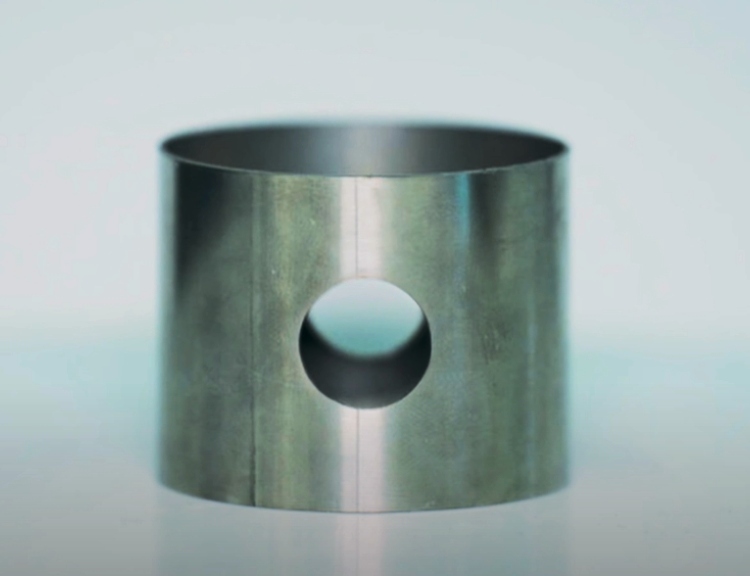

Precision Manufacturing Process

High-strength welded machine tool, processed by stress relief annealing method, high strength, not easy to be deformed, maximum load-bearing capacity up to 1000KG.

Super load bearing

Machine bed bears up to 1000KG, ideal for heavy – duty work.

Low vibration

Advanced design keeps vibration below 0.05mm for smooth operation.

High precision

Achieves ±0.02mm positioning accuracy for intricate cuts.

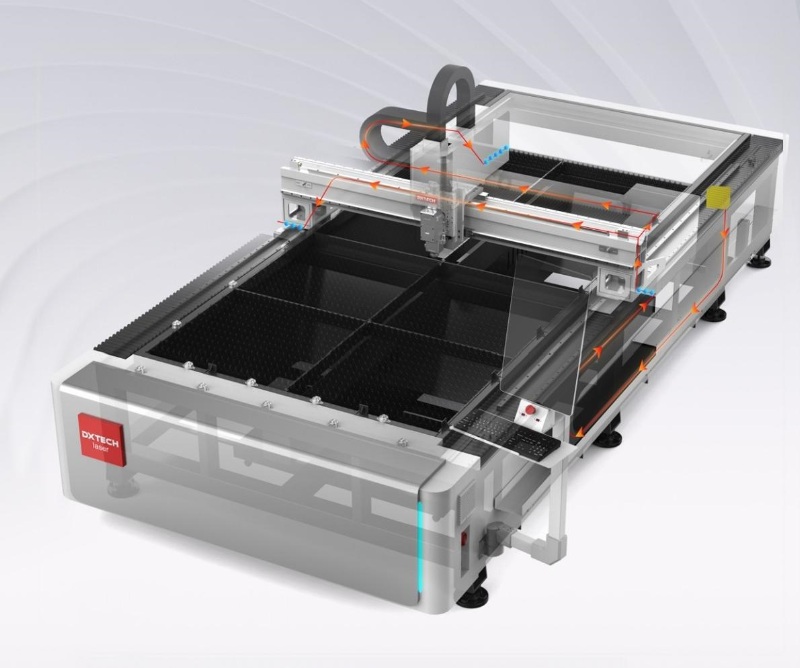

Optimized Exhausting System

The new – generation design, with German technology, has a large – front – small – back air outlet. This ensures stable ventilation and boosts the ventilation system’s performance, enhancing air exchange efficiency by up to 40%.

All-round Smart Automatic Lubrication

Lubricant automatically covers up to 11 points to ensure stability and 20% longer service life.

Low – oil alarm. Replenishing lost lubricant cuts breakdown risk by 50%

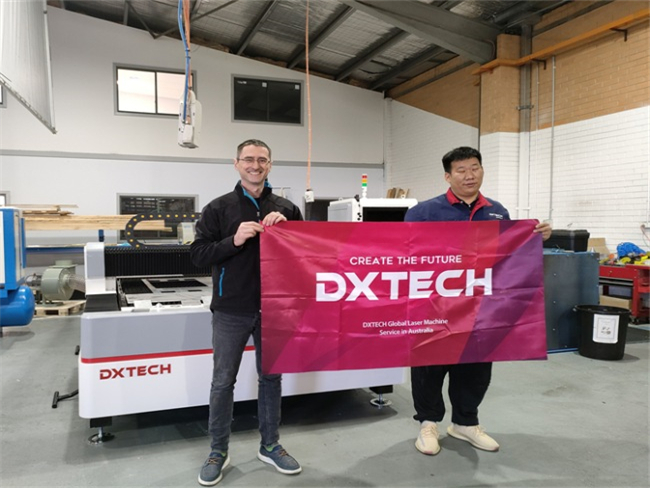

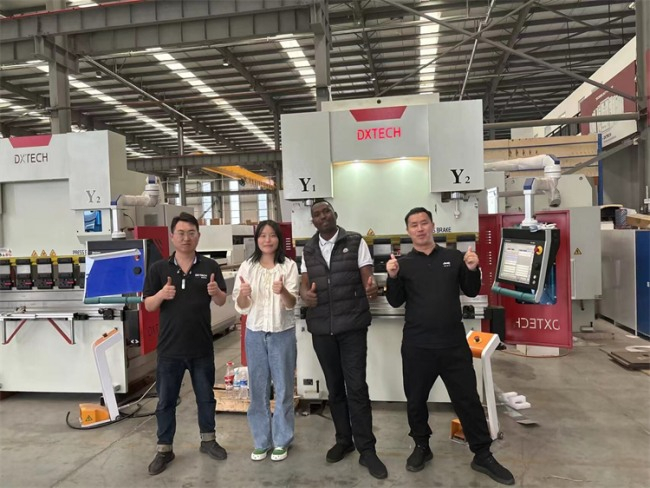

About DXTECH

strict quality control

Strict quality control system is implemented throughout the production process, with each machine undergoing an average of 160 inspections.

after-sales service

Provide 2 years warranty, lifelong technical guidance and support

Scale Advantage

Highly specialized factory with more than 75,000 square meters.

factory direct sale

Directly from the factory, no middleman

Fiber Laser Tube Cutting Machine Application

Furniture industry

For metal tables, metal chairs, metal beds, metal closets, metal shelves, metal light fixtures, and metal kitchenware.

Kitchenware industry

For sheet metal parts for appliances such as refrigerators, air conditioners, washing machines, ovens, hoods, etc.

Shipbuilding Industry

Cut and process bulb flat steel and other required plates, T – section steel, etc. needed for shipbuilding, such as ship keels, etc.

Automotive industry

Cutting of sheets for various components required for automobile manufacturing, such as car doors, bodies, components, car awning, trunk etc.

Advertising Industry

Cutting of plates required for various parts of the main advertising signs, such as door signs, door number plates, building name plates, outdoor guide signs, etc.

Fitness Industry

Mainly cuts the plates needed for each component, such as treadmills, exercise bikes and other fitness equipment manuafacturing.

One-Stop Solution for Your Confusion

Whether it’s laser cutting machine parameters, maintenance, or the purchase process, DXTECH’s pros are here to answer your questions and set you on the path to efficient processing.

FAQ

According to the material type (carbon steel / stainless steel / aluminum, etc.), thickness (0.5-50mm), cutting efficiency needs to choose the corresponding power (1.5kW-20kW) and model (plate / tube / coil).

The ambient temperature should be ≥5℃ to prevent the laser from condensation; regularly check the guide rail lubrication system; long-term shutdown needs to empty the cooling circulating water.

Online consultation → Confirmation of demand → Customized plan → Contract signing → Manufacturing → Acceptance and delivery → After-sales training.

Standard model: 30-45 days; Customized model (with automation): 60-90 days; Rush orders can be expedited by negotiation.

2 years machine warranty, laser 5 years warranty; 7 × 24 hours remote technical support, 48 hours on-site service; lifelong free process upgrade guidance.

Get a one-on-one customized solution

Any inquiries about the machine are welcome