CNC Press Brake Machine

Welcome to DXTECH PRESS BRAKE, where precision and reliability meet in hydraulic press brake technology. As leaders, we offer outstanding machinery that exceeds expectations, helping businesses succeed. With innovation, advanced tech, and flawless craftsmanship, we’re the top pick for unmatched accuracy and performance.

Join us to explore hydraulic press brakes and discover what makes DXTECH a trusted name.

Press Brake List

DXTECH High Precision Press Brake

PB-125T/2500 Electro-hydraulic Servo CNC Sheet Metal Bending Machine

The electro-hydraulic servo CNC bending machine ensures precise and versatile metal shaping. With the reliable Delem DA-66T CNC system, its welded structure and advanced vibration aging deliver high accuracy (≤0.02mm) and durability, even under extreme conditions.

DXTECH High Efficiency CNC Press Brake

DX-C2500 Pressure Arm Type Automatic Plate Bending Center

The automatic plate bending center excels in high-volume bending for thick metals, using multi-axis linkage to reduce mold and labor reliance. Fully automated, it boosts efficiency, cuts costs, and drives industrial transformation.

DXTECH New Design CNC Press Brake

DX-C1500 Suction Cup Automatic Panel Bending Machine for Sale

The suction-cup automatic panel bender excels in high-speed bending for thin metals and small parts, with minimal error and high consistency. Fully automated, it achieves 0.5 seconds per bend, boosting efficiency and reducing costs while driving industrial transformation.

DXTECH Hydraulic CNC Press Brake

DXTECH Sheet Metal Roll Forming Machine With Hydraulic Uncoiler

DXTECH hydraulic forming machine processes metal into various shapes and sizes with high efficiency and quality. It handles uncoiling, leveling, forming, bending, cutting, and drilling in one go, ensuring smooth surfaces without marks. Customizable to meet industry needs.

DX-PB-300T/3200 Electro Hydraulic Servo CNC Plate Press Brake Bending Machine

The electro-hydraulic servo CNC press brake efficiently bends various metal materials into diverse shapes using interchangeable molds. Equipped with the Delem DA-66T CNC system, it features a welded steel structure and vibration aging technology for high strength and rigidity.

Economical Twisted Axis CNC Press Brake Machine with E21 Control System

The economical torsion axis CNC bending machine reliably bends various metal sheets into diverse workpieces using interchangeable molds. Suitable for multiple materials, it operates stably and efficiently, serving industries like shipbuilding, automotive, and power.

DX-125T/3200mm ESA 630 CNC Press Brake Machine

The DXPB-125T/3200 Hydraulic NC Press Brake is our top-selling model, designed for stability and precise bending. Its responsive framework ensures reliability, making it essential for metallurgy-related enterprises.

Other Machines

DXTECH 80T2000mm CNC Press Brake Machine

CNC Automatic Channel Letter Bending Machine For Advertising

DX-11NC-6*3200 Plate Cutting Shears For Sheet Metal

DX-TP10S Twisted Axis CNC Press Brake Machine

DXTECH Hydraulic Press Brake Bending Machine

DXTECH 125T/3200 Hydraulic Press Brake Machine

Why choose DXTECH?

Highly professional

DXTECH boasts an impressive 75,000 square meter facility and brings 16 years of industry expertise to the table. Backed by a skilled technical team of over 300 professionals, we have earned the trust and recognition of customers across more than 180 countries and regions worldwide.

Comprehensive service system

We offer free pre-sales consulting for laser cutting machines, crafting tailored, cost-effective solutions, with 24/7 online/offline after-sales support including remote or on-site assistance

Quality Assurance

Each product has a 2-year warranty and provides free lifetime technical support.

Why Choose DXTECH Press Brake Machines?

- High Precision Machines

The machine frame features an integrated welding and machining structure, with all core functional components sourced from premium imported suppliers, ensuring comprehensive reliability and overall precision. - State-of-the-art Equipment

The DE-15 CNC system of German Alpha Company is adopted, which reduces the installation of pipelines and ensures the working stability and appearance of the machine tool.

Press Brake Machine Application

Kitchenware Industry

Laser cutting is common in the kitchen and bathroom industry, ensuring smooth edges and scratch-free surfaces for stainless steel panels under 3mm, while cutting costs on further processing.

Automotive Industry

The growing automotive industry requires advanced manufacturing, where laser CNC machines excel by providing efficient, automated solutions and driving supplier opportunities.

Fitness equipment industry

The growing demand for fitness equipment, such as bikes and outdoor workout tools, has increased the use of CNC laser cutting in manufacturing. This method offers high versatility for tube cutting, improved quality, and enhanced performance compared to traditional processes.

Shipbuilding industry

Advances in shipbuilding technologies have improved materials and construction, with Fiber laser cutting machines tailored to ship processing needs and industrial production methods.

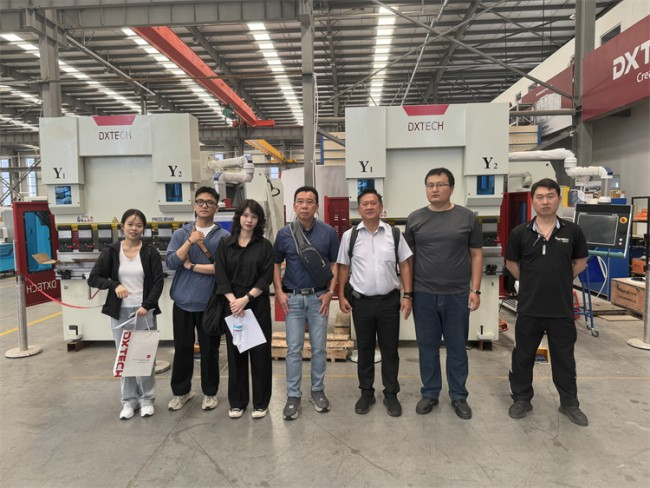

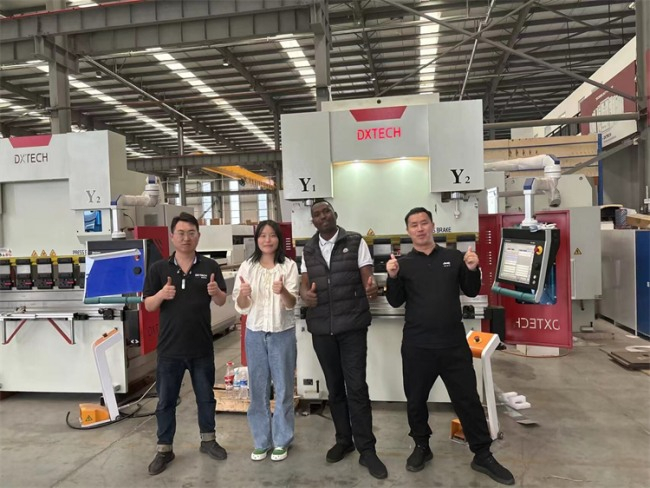

Cooperation Cases

FAQ

A press brake is a CNC-operated machine designed to bend and shape sheet metal. It features a ram for bending and a bed to secure the material. With CNC controls, it ensures faster, more precise, and consistent bends compared to traditional press brakes.

When choosing a press brake, keep these key aspects in mind:

- Material: Determine the type and thickness of the metal to be processed.

- Bending Length: Select a working length that matches the maximum size of your workpiece.

- Pressure: Ensure the machine provides adequate pressure for the material’s thickness and strength.

- Precision: Assess your accuracy needs and pick a suitable control system.

- Efficiency: Consider your daily production requirements to choose the right level of automation.

- Budget: Opt for equipment that balances cost-effectiveness with your needs.

This machine is suitable for any material preparation workshop, and its conditions are:

1) Power supply voltage: three-phase 380V AC-+10%

Frequency: 50HZ±1HZ

2) Operating environment temperature -20—+50℃

Humidity 20-85% (no condensation, no condensation)

Altitude<1000m

3) Protection level electrical control cabinet IP40

Control box IP45

This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

For daily press brake maintenance:

- Cleanliness: Keep the machine free of dust and debris.

- Lubrication: Follow the manual to lubricate moving components regularly.

- Hydraulic System: Check for normal oil levels and ensure there are no leaks.

- Electrical System: Verify secure connections and undamaged wiring.

- Calibration: Regularly inspect and adjust bending accuracy.

- Consumables: Replace molds and other worn parts promptly.