| Fiber Laser Welding Machine

Fast welding speed • Easy to learn and operate • Consistently high-quality results

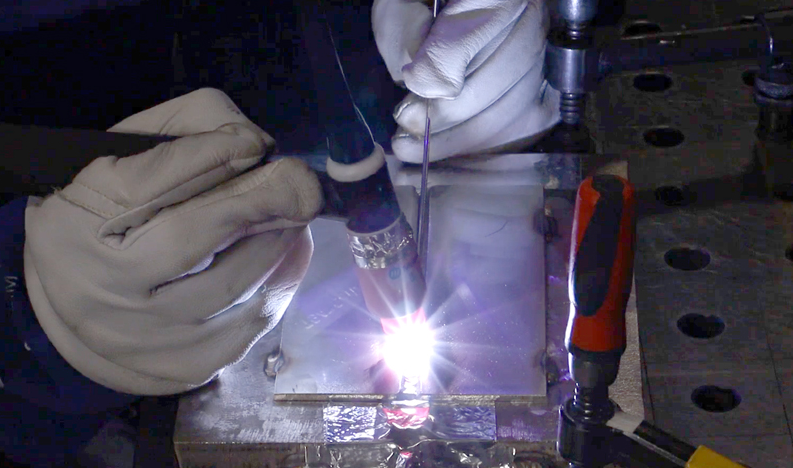

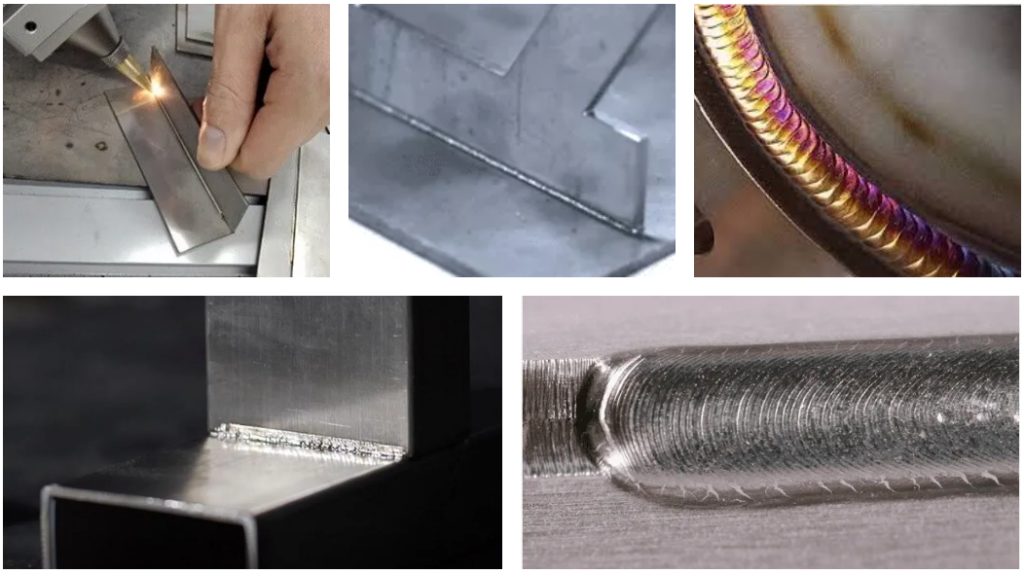

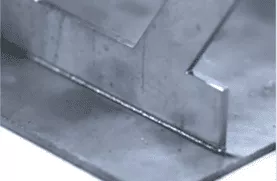

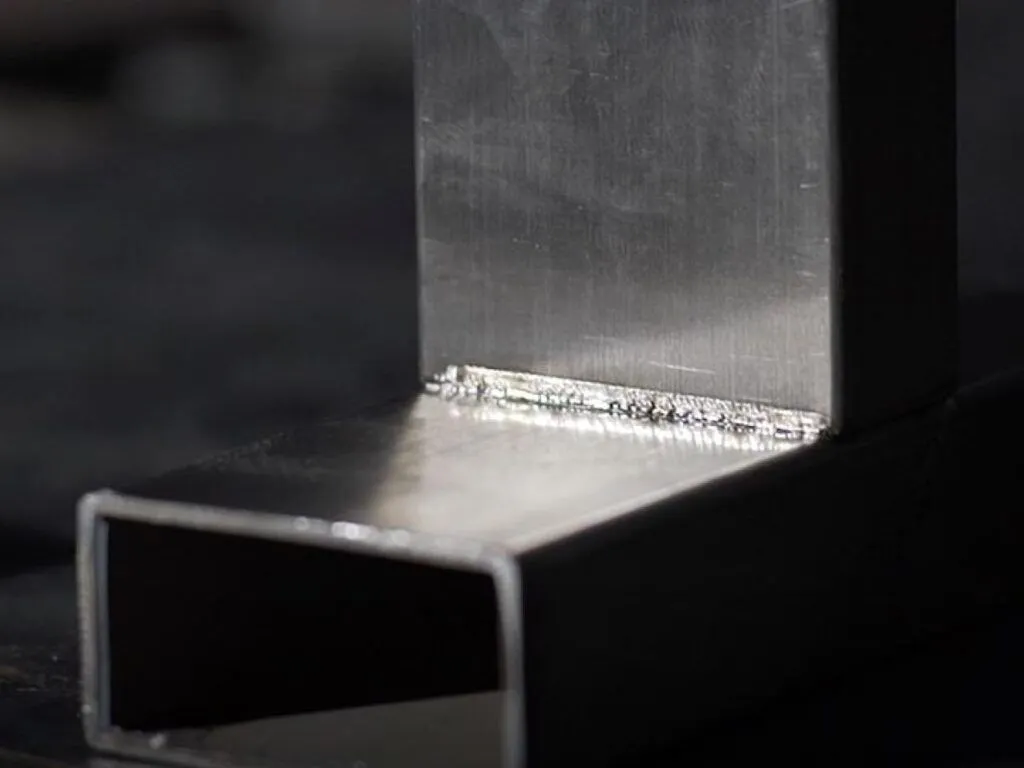

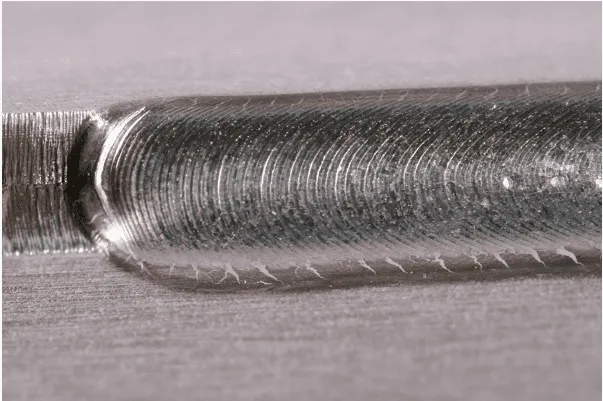

Fiber laser welding machine adopts non-contact welding method to generate high-intensity beam. When the beam is focused to one point, it can provide a concentrated heat source, thereby realizing narrow and deep welds and fast welding, and can realize spot welding, butt welding, lap welding, sealing welding, etc. Laser welding machine can weld various types of metal materials, such as steel, stainless steel, aluminum, brass, etc., and can also weld different thicknesses and shapes according to customer needs.

DXTECH Laser has various types of high-end laser welding machines, such as professional handheld welding machines, 3-in-1 handheld welding machines, portable laser welding machines, fully automatic laser welding machines, automatic 6-axis fiber laser welding robots and other models. Tailor-made solutions can be developed according to the specific needs of industries and customers.

Features of DXTECH laser welding machines:

- Small heat affected zone, less prone to deformation, produces better welding results.

- Easy to apply, 4 times faster than traditional handheld welding processes (tig, mig).

- High-precision welding without costly rework and post-processing.